Radium Fuel Pump Hanger w/Integrated FPR

Ford Mustang S197/S550 11-21/S650 23+

This product is in stock & ready to be dispatched.

This product has very limited stock remaining.

Product will be in stock soon.

This product is not ready for immediate dispatch and will ship in the timeframe displayed.

This product is not available at this time. Request ETA Information

Earn [points_amount] when you buy this item.

Description

Description

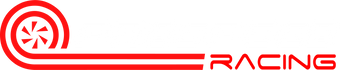

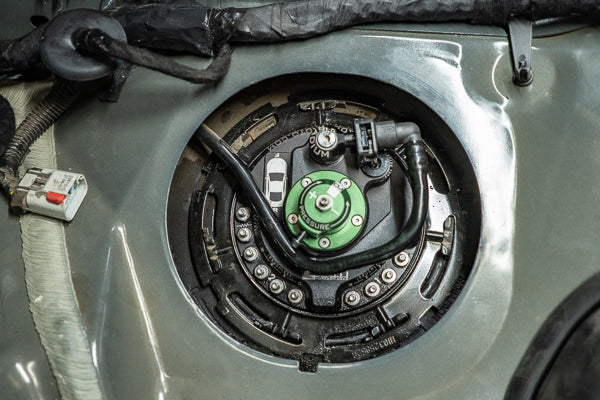

The Radium Engineering pump hanger is an excellent solution for adding the proper amount of fuel flow for modified 2011+ S197/S550 vehicles. It can be used with 1 or 2 aftermarket pumps. Fuel pressure is regulated and supplied to the engine at a 1:1 rate. The system is compatible with all alternative fuels. The OEM fuel tank access cover and rear seat bench fit without modifications.

Features:

- Drop-In Installation

- Permits 1 or 2 Pumps

- Integrated 1:1 Adjustable FPR

- Fuel Starvation Protection

- High Current Electrical Hardware

- Compatibility with Popular Fuel Pumps

- Anodized Aluminum Construction

- Gasoline, Methanol, Ethanol Compliant

- Fuel Resistant Tubing and Wiring

- Stainless Steel Hardware

STARVATION PROTECTION

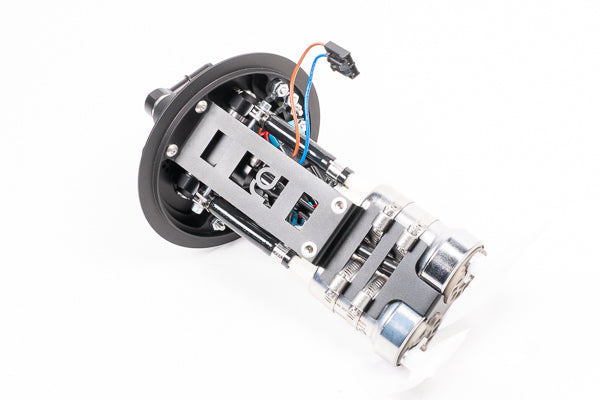

The internal pump(s) are supplied with fuel from 3 different sources: the venturi jet pump fuel scavenged from the passive side of the tank, the returned fuel from the integrated fuel pressure regulator, and the two 355LPH one-way fill valves on the bottom of the collector box (shown below) that allows fuel in, but not out.

This ensures that pump(s) feeding the engine are always supplied with fuel, even in extreme driving conditions.

INTEGRATED FPR

Because the Ford fuel system is "returnless", forced induction tuning can be problematic when a 1:1 fuel to boost pressure ratio is not possible. Like the OEM setup, a fuel pressure regulator (FPR) is integrated into the Radium fuel hanger. The difference is the regulator can withstand high flowing fuel pumps. Also, the regulator is externally mounted with an adjustment screw and a vacuum port. If an intake manifold vacuum hose is connected, the built-in FPR will operate at a 1:1 ratio permitting fuel pressure to proportionally increase with manifold (boost) pressure. Conversely, the vacuum port can remain open to atmosphere and pressure will remain constant (like OEM).

The returning low pressure fuel from the FPR is sent back into the FST collector box keeping it full. Also, 2 fuel return orifices are included for fine-tuning the desired fuel pressure to the fuel pumps' flow rate and potential hose plumbing restrictions. Refer to the installation instructions link above for more details.

NOTE: The Radium integrated regulator should be the only FPR in the fuel system.

PLUMBING

The fuel pump outlet port is 3/4"-16 thread tapped (8AN ORB). Because the 2 unibodies (S197/S550) use different fuel feed line connections, two unique low profile SAE quick connect fittings are provided. This can always be changed using an 8AN ORB fitting. The return port is only required to be used if the 20-0806 Fuel Hanger FPR Block-Off (see below) is installed. It is 9/16"-18 thread tapped (6AN ORB). A plug is preinstalled in this port. This can always be changed using an 6AN ORB fitting.

Always install a sock filter to the fuel pump inlet(s). Compatible sock filters are located HERE. The fuel hanger eliminates the OEM post pump filter in the factory unit.

A low micron aftermarket filter is required to be installed downstream to protect the injectors from debris.

VENTURI JET PUMP

The OEM venturi jet pump in the return line creates a restriction when using high flowing fuel pumps. Radium Engineering has redesigned the siphon system to eliminate this restriction but still effectively scavenge fuel. This means higher flowing pumps can safely be used without fuel pressure issues. Depending on fuel pressure, the venturi jet pump will consume 15-45 LPH. Take this fuel loss into consideration when sizing the fuel pumps. Connection to the crossover venturi system is made easy with the provided SAE quick connections (shown below).

Also, if it is important for fuel pressure to hold steady after the engine is shut down, install a CHECK VALVE somewhere in the fuel system.

ELECTRICAL

The custom designed stainless electrical studs easily handle the high current demand that compact multi-pin bulkhead connectors lack. These serviceable connections are hermetically sealed and impervious to all standard and exotic fuels. Non conductive anodized aluminum acorn nuts are provided to prevent any accidental short circuiting. Electrical hardware is included for the fuel pump(s) and OEM level sender. Furthermore, the in-tank wiring is insulated with high quality chemically resistant ETFE.

Depending on the specific model trim, the OEM fuel pump wiring is designed for 15-30 amps of current. Depending on the pump installed, the fuel pump controller wiring can be reused for a single pump (only). Radium recommends upgrading the wiring to ensure the fuel pumps are operating at their full potential. Universal fuel pump wiring kits can be found HERE. Select one for each aftermarket pump used.

The OEM fuel level sensor secures to the collector box mount shown.

PUMP COMPATIBILITY

Brushed and brushless fuel pump options are compatible. The system is suited, but not limited, to the following fuel pumps:

- Walbro F90000267 E85

- Walbro F90000274 E85

- Walbro F90000285 E85

- Walbro GSS342 255lph

- AEM 50-1200 E85

- Deatschwerks DW400

- Ti Automotive BKS1000 (brushless)

- Injector Dynamics BPC-1100 (brushless)

NOTE: Because the brushless E5LM fuel pump does not have an integrated check valve, P/N: 20-0801-00 contains two bolt-on check valves. This permits pump staging which is common when using multiple fuel pumps.

OPTIONAL 20-0806 FUEL HANGER FPR BLOCK-OFF

This kit bypasses the integrated fuel pressure regulator on the Radium fuel hangers (20-0800, 20-0801, 20-0802) to permit an external fuel pressure regulator.

As shown, a viton O-ring, anodized aluminum plate, and stainless steel plug are included.

NOTES:

- 6AN ORB fitting is required for the return port. Keep in mind, if the rear seat will be retained, this fitting must be low profile (example shown).

- A fuel pressure regulator (not included) must be installed downstream in the system. This procedure is not discussed in the instructions.